According to a report from the United Nations Conference on Trade and Development (UNCTAD), the surge in global container freight rates may increase global consumer prices by 1.5% next year and import prices by more than 10%. China's consumer prices may rise by 1.4 percentage points as a result, and industrial production may be dragged down by 0.2 percentage points.

UNCTAD Secretary-General Rebeca Grynspan said: “Before shipping operations return to normal, the current surge in freight rates will have a profound impact on trade and undermine the socio-economic recovery, especially in developing countries.”

01 Global consumer prices will increase by 1.5% overall

After the COVID-19 pandemic, the global economy has gradually recovered, and shipping demand has surged, but shipping capacity has never been able to return to the pre-epidemic level. This contradiction has led to soaring ocean shipping costs this year.

For example, in June 2020, the spot price of the Container Freight Index (SCFI) for the Shanghai-Europe route was less than USD 1,000/TEU, and it had jumped to approximately USD 4,000/TEU by the end of 2020, and had soared to USD 7,395 by the end of July 2021. . In addition, shippers also face shipping delays, surcharges and other costs.

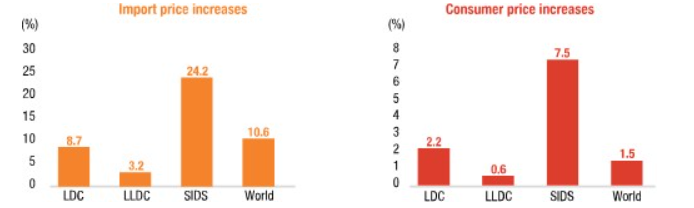

The United Nations report said: "the analysis of the United Nations Conference on Trade and development shows that between now and 2023, if container freight rates continue to soar, the global price level of imported products will rise by 10.6% and consumer prices will rise by 1.5%."

SThe impact of soaring shipping costs on different countries is different. Generally speaking, the smaller the country and the higher the proportion of imports in the economy, the more affected countries are naturally. Small Island Developing States (SIDS) will be the most affected, and the soaring cost of shipping will increase consumer prices by 7.5 percentage points. Consumer prices in landlocked developing countries (LLDC) may rise by 0.6%. In the least developed countries (LDC), consumer price levels may rise by 2.2%.

02 Import prices and consumer prices in different types of countries are affected differently

By country, as the cost of shipping soars, the US consumer price index will rise by 1.2%, and China will rise by 1.4%; by product category, the prices of electronic products, furniture and clothing will be most affected by the increase in shipping prices. The internal increase is at least 10%.

03 Economic growth and industrial production will also be affected

The analysis also said that the soaring cost of container transportation will also drag down the economic growth of major economies. According to the report, if the supply chain continues to be disrupted and container freight rates rise by 10%, industrial production in the United States and the Eurozone will fall by 1%, and industrial production in China will fall by 0.2%.

Swiss logistics giant Kuehne+Nagel said that as of the end of October, more than 600 container ships worldwide were trapped outside the port, twice the level at the beginning of the year. At the end of last month, the company predicted that port and route congestion will continue until at least February next year.

04 How far is the supply chain crisis?

The most deserted Thanksgiving in history, supermarkets limit purchases of daily necessities: the timing is close to the two major shopping holidays of Thanksgiving and Christmas in the United States. However, many shelves in the United States are not full. The out-of-stock problem that would only occur on Christmas Eve originally started 2 months earlier. Ferment. Bottlenecks in the global supply chain continue to affect US ports, highways, and rail transportation. The White House even frankly stated that consumers will face more serious shortages in the 2021 holiday shopping season.

The global supply chain is currently facing a serious crisis. Recently, in American stores, supermarkets, and even hypermarkets, food, beverages, clothing and daily necessities are often out of stock. Supermarket shelves are not fully complemented, and there are fewer product choices. Stores are not sure when they will be able to replenish them, and even remove shelf labels. Even large supermarket chains have also resumed the "purchase restriction" policy, restricting the amount of daily necessities such as toilet paper for customers to purchase just like when the epidemic first broke out. This supply chain crisis has put tremendous pressure on the global retail and transportation industries. Some companies have recently issued a series of pessimistic financial forecasts, and the impact continues to expand.

The White House is working hard to get the U.S. ports, rail, and road transportation out of trouble, and solve the problem of insufficient supply from meat to semiconductors. However, US officials still warn that the Christmas shopping season in 2021 may face higher prices and severe shortages. Although American consumers are not used to empty shelves, they need some flexibility and patience.

How did this crisis happen? Multiple factors prevent the goods from being delivered to the United States immediately. The first is the shortage of containers. The shortage of containers has caused container prices to be 10 times higher than in the past. According to Time Magazine, a 40-foot container was shipped from China to the United States before the epidemic. The asking price was about US$4,700, which rose to US$21,000 in August. It is now necessary to pay higher costs to transport goods from the place of production to the United States.

The port congestion on the West Bank is serious, and it takes one month for cargo ships to unload: the port congestion problem is still serious. Cargo ships lining up on the west coast of North America can take up to one month to dock and unload. Various consumer products such as toys, clothing, and electrical appliances are out of stock. In fact, the port congestion in the United States has been severe for more than a year, but it has deteriorated since July. Lack of workers: Lack of work has slowed the speed of unloading at ports and truck transportation, and the speed of replenishment of goods is far below demand.

The US retail industry orders early, but the goods still cannot be delivered: In order to avoid a serious shortage of goods, US retailers have resorted to their best efforts. Most companies will order early and build inventory. According to data from UPS's delivery platform Ware2Go, as early as August, as many as 63.2% of merchants ordered early for the holiday shopping season at the end of 2021. About 44.4% of merchants had higher orders than previous years, and 43.3% were more than ever. Order early, but 19% of merchants are still worried that the goods will not be delivered on time.

There are even operators who rent ships themselves, find air freight, and try their best to speed up logistics. For example, Wal-Mart, Costco, and Target all employ their own ships to ship thousands of containers from Asia to North America. Costco Chief Financial Officer Richard Galanti pointed out that three ships are currently employed, each of which is expected to carry 800 to 1,000 containers. However, if it is only a small and medium-sized retailer or a new brand, not only can it not negotiate directly with the shipping company, the cost of hiring cargo ships and air freight is too high and cannot afford it. The monthly cost of chartering a cargo ship may be as high as US$1 million to US$2 million.

The global economy is just about to recover from the chaos caused by the epidemic, but it is facing an extreme shortage of energy, components, products, labor, and transportation. The global supply chain crisis seems to have no signs of resolution. Coupled with the sharp increase in production costs, consumers will obviously feel the price increase. This Christmas holiday in the United States may not be so good.

Contact: Manager Gao

Phone: +86-15932423630

Tel: +86-311-89276065

Email: mesh@ht-mesh.com

Add: Wire Mesh Zone,Anping County,Hebei Province,China.