Ruitong Metal Products Quality Control

Ruitong Metal Products Quality Control

|

We offer you a wide range of raw materials for the production of expanded metal mesh Mild steel plate, stainless steel plate, aluminum plate, copper plate, nickel plate, titanium plate, ruthenium-iridium plate Aluminum-magnesium alloy plate and other metal plates. expanded metal mesh can be produced very thin suitable for a variety of high-end precision instruments onThe unique "stamping and stretching" expansion process produces zero scrap and can be achieved with veryvery small, precise openings to achieve in addition up to 95% open area. |

|

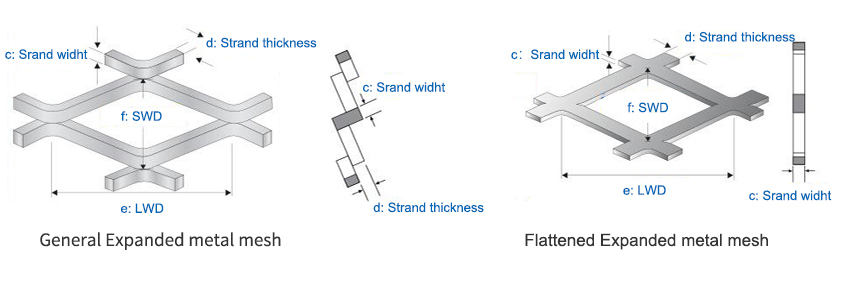

Necessary parameters: a:Material b:Flattening method c:Strand width d:Strand thickness e:Longway of mesh (LWD) f:Shortway of mesh (SWD) g:Hole type h:Surface treatment i :SWM, LWM |

|

Long way of the diamond (LWD) – Measured from the center of one node to the center of the adjacent node, the LWD is always parallel to the width of the coil and corresponds with the diamond dimension. Short way of the diamond (SWD) – Measured from the center of the node to the center of the node, the SWD is perpendicular to the width of the coil. For each fixed LWD dimension there is a SWD range. Strand width – The amount of metal slit from the parent metal in forming the mesh. The strand thickness is directly proportional to the machine feed rate. |

|

|

|

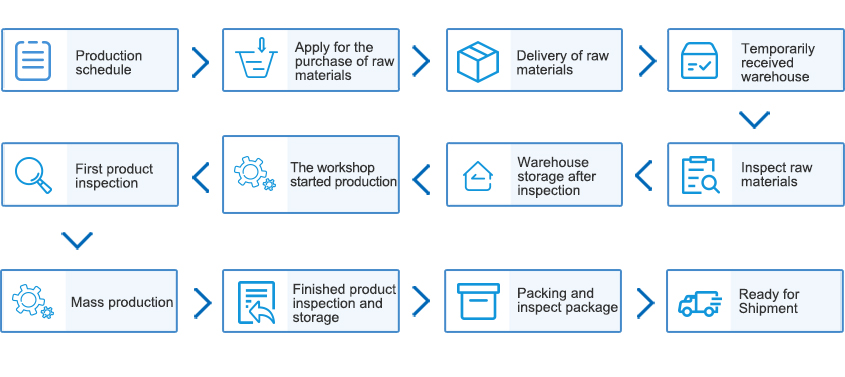

Step 1 Communicate with you about the specifications, materials, and other product-related issues you need, and prepare for production preparation. |

|

Step 2 Next, we select the right tooling mold according to your product specifications and start production. |

|

|

|

Step 3 Then, the expansion process of stamping and stretching begins on the machine with uniform mesh holes. |

|

|

Step 4 The plate is stamped and the next surface treatment is applied according to the requirements. |

|

|

|

Step 5 Finally, the expanded metal mesh is checked for dimensions and some necessary tests are done to ensure the product can meet your needs. |

Contact: Manager Gao

Phone: +86-15932423630

Tel: +86-311-89276065

Email: mesh@ht-mesh.com

Add: Wire Mesh Zone,Anping County,Hebei Province,China.